- Share

- Share on Facebook

- Share on X

- Share on LinkedIn

Circular manufacturing systems: unique environments facing numerous challenges.

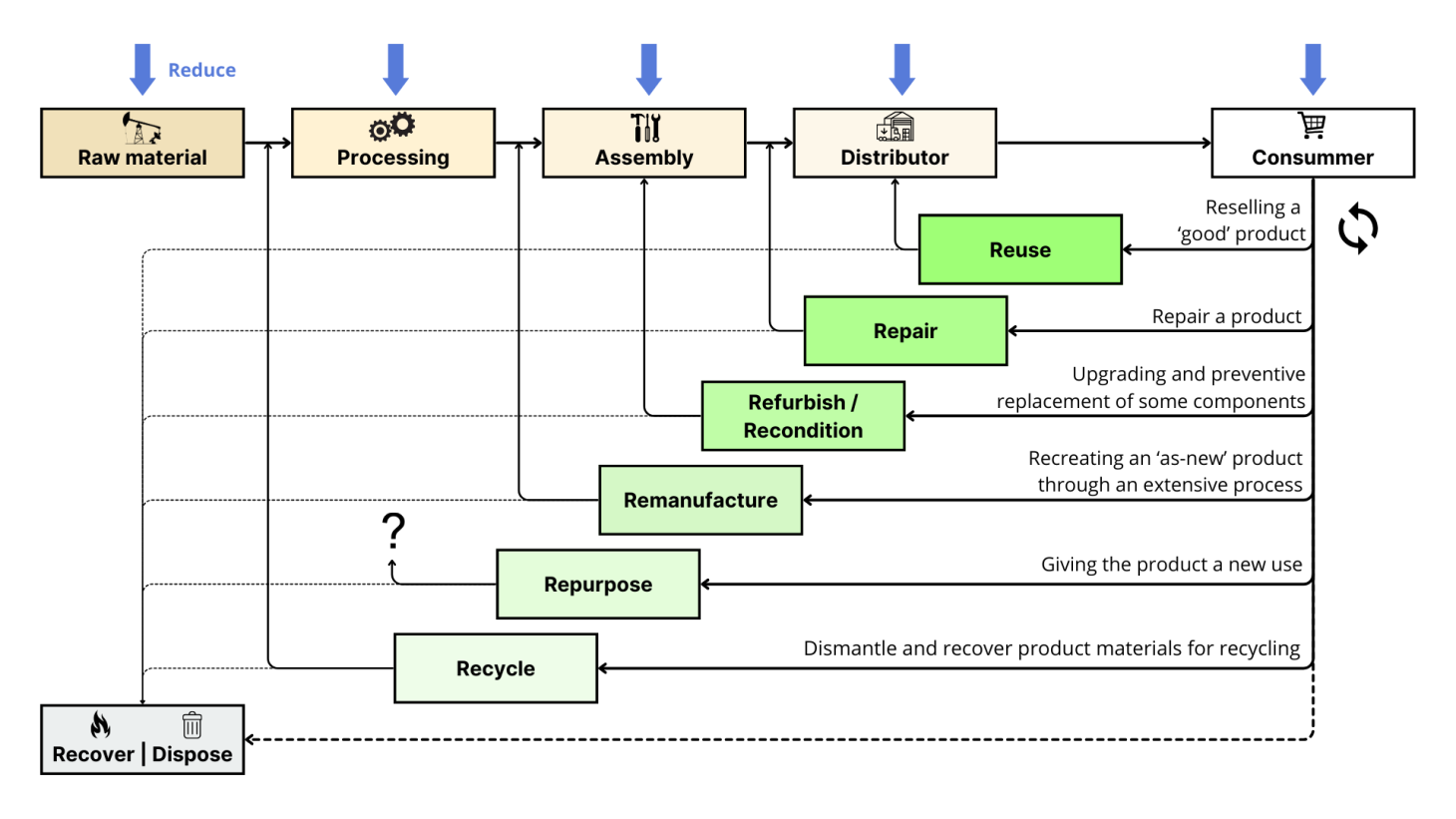

Among the various circular economy strategies that exist, putting products back into service is one of the most important. To do this, products that have already had a first life are collected. Several strategies can then be adopted to give the product a second life. These strategies range from simple re-use of the product to remanufacturing, which involves completely dismantling the product and putting it back into service in like-new condition to give it a whole new life. Intermediate strategies also exist between these two extremes, as shown in Figure 1.

To begin implementing these circular economy strategies, new production systems need to be put in place to allow products to be returned, disassembled, refurbished or upgraded. There are many economic, social and environmental barriers to the introduction of these systems. These plants face new challenges in terms of managing internal flows, product variability, uncertainties about the quality of inputs and the final product, and an increased need for traceability throughout the value chain.

These are summarised in the first article written as part of this project here and were for the most part confirmed through a dedicated industry survey, the summary of which can be found here [link coming soon].

Taking a variety of products in very different conditions, disassembling them, inspecting them, cleaning them, restoring them by repairing or changing components, and then reassembling them before reselling them is not a trivial process. It requires operators with extensive knowledge and skills to carry out operations that cannot always be standardised and requires many years of experience to find optimal solutions for recreating a quality product while preserving health. One of the major challenges for the development and deployment of circular production systems therefore lies in the training of these operators. The operator is at the heart of the circular production system and is key to its performance. They are also put to the test, both physically and cognitively. Circular operations frequently place intense demands on the operator's muscles (particularly when cleaning or disassembling), or on their thinking to find strategies for dismantling and repairing parts that were not designed for these processes. Circular production systems cannot therefore be studied without taking into account of operators and their health. The proposed study takes particular account of these aspects thanks to the inclusion of researchers in ergonomics and occupational psychology.

Are new technologies a solution to the challenges of circular production systems?

Faced with the emergence of new technologies in linear production systems, several scientists have examined their applicability in circular systems. Many predict that emerging digital technologies will be necessary for this transition from the linear economy to the circular economy. In particular, transformations are expected in product design, value chain management and production workshops. Some of the technologies presented under the term emerging digital technologies are shown in Figure 2. Industry 4.0 or 5.0 is often used to refer to these emerging digital technologies.

Nevertheless, there is a real gap in demonstrating the benefits of these emerging technologies, but also the difficulties associated with their implementation. A literature review - available here - has been carried out to highlight the opportunities and barriers associated with these technologies, as well as the technological promises that have been made about the use of these technologies in circular systems. In addition to the predominance of articles extolling expected or hoped-for benefits without providing concrete, empirical evidence, few studies adopt a multidisciplinary, systematic approach to the subject. In a production context that aims to be more respectful of the environment and human beings, neglecting the environmental and social aspects would appear to be heresy.

The economic aspect should not be overlooked either. The profitability of circular activities can be highly variable and highly dependent on product returns, and the high levels of investment associated with certain new technologies are not always feasible. There is therefore a need to find

Research objectives

In this context, one of the studies in the CIRCULAR project aims to explore the concrete contributions of some of these emerging technologies through technical or experimental evidence to facilitate the implementation of the circular economy in industry. The study will also take into account different perspectives, including ethical and sustainable aspects.

This work will be based on several research methodologies, including an industrial case study, physical simulations on a laboratory technology platform and numerical simulations.

(© Grenoble INP)

The various objectives of the research project can therefore be summarised as follows:

- To define a methodology for designing a circular production workshop, the stages of which take account of the particularities of the circular economy and suggest digital technologies that are relevant to the three pillars of sustainable development at the various stages of implementing these systems.

- Determine whether the technologies of the industry of the future will be adequate resources for running workshops in a circular economy context, by adopting a multidisciplinary approach combining engineering and human sciences.

- Provide technical or experimental evidence of the contribution of certain emerging technologies to the implementation of production systems in a circular economy context.

Read the articles published as part of this thesis here

maxence.denu grenoble-inp.fr (Contact)

grenoble-inp.fr (Contact)

- Share

- Share on Facebook

- Share on X

- Share on LinkedIn